- Home

- Sprocket

- Standard Sprocket

- Stainless Steel Engineering Class Sprockets

Stainless Steel Engineering Class Sprockets

$00 $00

Stainless Steel Engineering Class Sprockets

- General Details

- Our Service

- Packing & Delivery

- Order Enquiry

Product Description

Standard Sprockets | Stainless Steel Engineering Class Sprockets

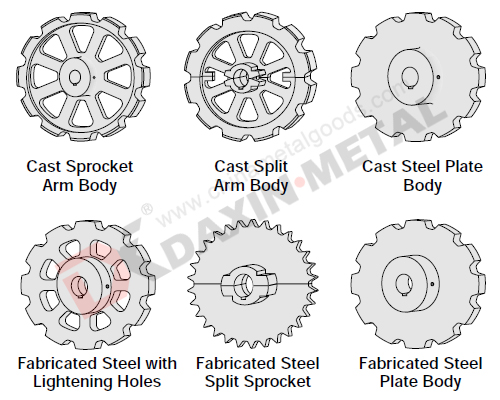

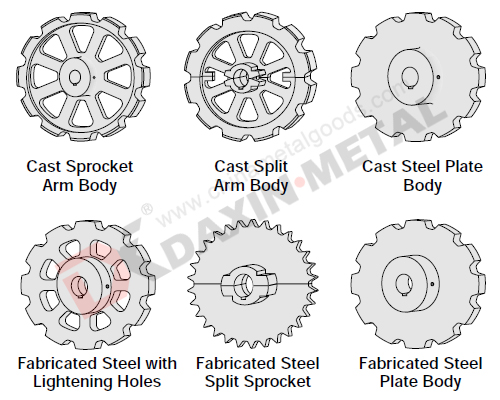

According to the structure design, the roller chain sprocket-wheel can be classified into simplex, duplex,triplex types, and type A,type B, Stainless Steel Engineering Class Sprockets.

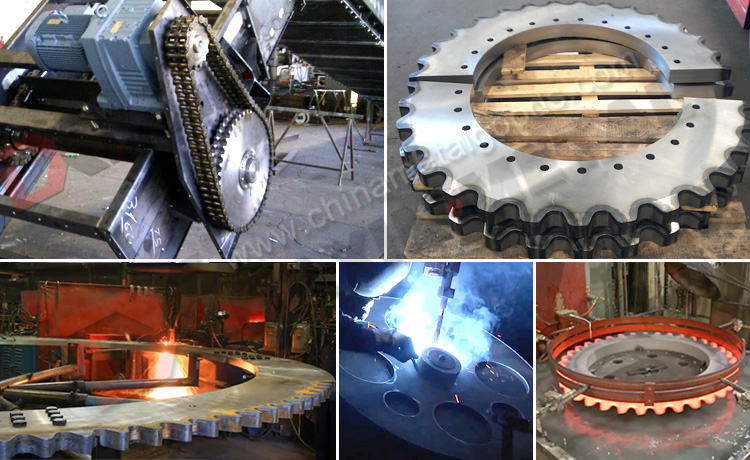

cast fabricated steel sprocket

Our Stainless Steel Engineering Class Sprockets is made of medium carbon steel through integral forging process. The sprockets teeth are created by specialized gear hobbing machines and CNC machine.

Our machining methods include CNC machining, spline, thread rolling, gear hobbing, teeth cutting, centerless grinding, finishing. Also we can do it by boring, drilling, milling, turning, broaching, tapping, wire EDM.

The Stainless Steel Engineering Class Sprockets undergoes integral quenching and tempering, so as to offer superior mechanical performance as well as high strength and deformation resistance. Due to this, it supports working with high load. Through high frequency quenching, the teeth of our roller chain sprocket come with high hardness and superb wearing resistance.

gear sprocket machining surface treatment

Non-standard Sprockets | Stainless Steel Engineering Class Sprockets

As a Stainless Steel Engineering Class Sprockets manufacturer and exporter based in China. we can design various non-standard sprocket products according to drawings. If you need tailor-made sprockets, please tell us specifications such as the chain pitch, roller diameter, and desired teeth number.

We are able to design and make customized roller chain sprockets wheel for mechanical power or rotary movement transmission purposes. According to the application demands, this range of Stainless Steel Engineering Class Sprockets can be processed into the welded type. This can save the user’s cost.

Product Applications | Stainless Steel Engineering Class Sprockets

Our Stainless Steel Engineering Class Sprockets are widely used on the industries such as agricultural machinery, engineering machinery, conveying machinery, food processing packaging machinery. Industrial equipment, chain transmission equipment, chemical, textile, food processing. And petroleum, sugar making, thermal power generation, mineral processing, production assembly lines for automobile parts and electronic parts.

We can produce Stainless Steel Engineering Class Sprockets, agricultural machinery sprockets, farm machinery sprockets, engineering machinery sprockets. And power transmission equipment sprockets, chain transmission sprockets. And we can produce food processing machinery sprockets, conveyor chain sprockets, packing machinery sprockets, assembly line sprockets, drive sprockets.

sprocket gear heat treatment inspection and packaging

Special Sprockets | Stainless Steel Engineering Class Sprockets

We manufacture Stainless Steel Engineering Class Sprockets and large heavy duty sprockets, often with bespoke tooth profiles. Many profiling options are available for sprockets. For high load precision applications, Daxin Metal can offer a fully machine cut sprocket, produced to the same high standards as our precision cut sprockets. For less demanding applications where cost is critical, we are able to offer a high quality flame cut profile. In order to manufacture a cost effective yet accurate tooth form, we can supply laser cut profiles for thinner materials.

These heavy duty sprockets are usually used in mining and quarrying, construction, marine/offshore, waste and recycling, water treatment. we are able to ensure that only the highest quality components are delivered, ensuring trouble free installation and the longest possible conveyor chain sprockets life for our customers.

We are also able to offer bespoke sprockets and Stainless Steel Engineering Class Sprockets branded, with our customers markings free of charge for large volume users.

product information

| Process | Machining, Forging , Casting |

| Material | C45(1045), A3(low carbon steel), 40Cr, 20CrMnTi, 42CrMo, Cast iron, Ductile iron, Copper, Stainless steel and so on as per your request |

| Heat Treatment | High frequency quenching, Carburizing, Shot peening, Quenching and Tempering, Nitriding |

| Surface Treatment | Blacking, Hot-dip Galvanizing, Hard Chrome Plating, Zinc Plating, Electroplating, Nickel plating, Sandblasting, Color painting Dacromet coating, Powder coating, customer requirement |

| Performance | Long lifespan, High precision, High wear resistance, High strength,Low noise, Smooth and steady, Fatigue strength |

| Model | Type A , Type B , ANSI, DIN , JIS Standard, Non-standard (single duplex and triple) 25A, 35A, 40A, 50A, 60A, 80A, 100A, 120A, 140A, 160A, 25B, 35B, 40B, 41B,50B, 60B, 80B, 100B, 120B, 140B, 160B, 180B, 200B, 240B |

| Packaging | Products carefully packaged,Inner plastic bag and outer carton box or customer requirement,after long distance transport or long time store, open the package, brand new, no damage no rust. |

Welcome your enquiry

When you work with Daxin Metal, you’ll have access to a professional team with years of experience fabricating Stainless Steel Engineering Class Sprockets.

For a timely quote, please complete and submit the following information. We are ready to address your questions and special requests to support you on your engineering challenge.

Our team will immediately reply your project inquiries to your email

Product Description

Standard Sprockets | Shot Peening C45 Steel Sprocket

According to the structure design, the roller chain sprocket-wheel can be classified into simplex, duplex,triplex types, and type A,type B, Shot Peening C45 Steel Sprocket.

cast fabricated steel sprocket

Our Shot Peening C45 Steel Sprocket is made of medium carbon steel through integral forging process. The sprockets teeth are created by specialized gear hobbing machines and CNC machine.

Our machining methods include CNC machining, spline, thread rolling, gear hobbing, teeth cutting, centerless grinding, finishing. Also we can do it by boring, drilling, milling, turning, broaching, tapping, wire EDM.

The Shot Peening C45 Steel Sprocket undergoes integral quenching and tempering, so as to offer superior mechanical performance as well as high strength and deformation resistance. Due to this, it supports working with high load. Through high frequency quenching, the teeth of our roller chain sprocket come with high hardness and superb wearing resistance.

gear sprocket machining surface treatment

Non-standard Sprockets | Shot Peening C45 Steel Sprocket

As a Shot Peening C45 Steel Sprocket manufacturer and exporter based in China. we can design various non-standard sprocket products according to drawings. If you need tailor-made sprockets, please tell us specifications such as the chain pitch, roller diameter, and desired teeth number.

We are able to design and make customized roller chain sprockets wheel for mechanical power or rotary movement transmission purposes. According to the application demands, this range of Shot Peening C45 Steel Sprocket can be processed into the welded type. This can save the user’s cost.

Product Applications | Shot Peening C45 Steel Sprocket

Our Shot Peening C45 Steel Sprocket are widely used on the industries such as agricultural machinery, engineering machinery, conveying machinery, food processing packaging machinery. Industrial equipment, chain transmission equipment, chemical, textile, food processing. And petroleum, sugar making, thermal power generation, mineral processing, production assembly lines for automobile parts and electronic parts.

We can produce Shot Peening C45 Steel Sprocket, agricultural machinery sprockets, farm machinery sprockets, engineering machinery sprockets. And power transmission equipment sprockets, chain transmission sprockets. And we can produce food processing machinery sprockets, conveyor chain sprockets, packing machinery sprockets, assembly line sprockets, drive sprockets.

sprocket gear heat treatment inspection and packaging

Special Sprockets | Shot Peening C45 Steel Sprocket

We manufacture Shot Peening C45 Steel Sprocket and large heavy duty sprockets, often with bespoke tooth profiles. Many profiling options are available for sprockets. For high load precision applications, Daxin Metal can offer a fully machine cut sprocket, produced to the same high standards as our precision cut sprockets. For less demanding applications where cost is critical, we are able to offer a high quality flame cut profile. In order to manufacture a cost effective yet accurate tooth form, we can supply laser cut profiles for thinner materials.

These heavy duty sprockets are usually used in mining and quarrying, construction, marine/offshore, waste and recycling, water treatment. we are able to ensure that only the highest quality components are delivered, ensuring trouble free installation and the longest possible conveyor chain sprockets life for our customers.

We are also able to offer bespoke sprockets and Shot Peening C45 Steel Sprocket branded, with our customers markings free of charge for large volume users.

product information

| Process | Machining, Forging , Casting |

| Material | C45(1045), A3(low carbon steel), 40Cr, 20CrMnTi, 42CrMo, Cast iron, Ductile iron, Copper, Stainless steel and so on as per your request |

| Heat Treatment | High frequency quenching, Carburizing, Shot peening, Quenching and Tempering, Nitriding |

| Surface Treatment | Blacking, Hot-dip Galvanizing, Hard Chrome Plating, Zinc Plating, Electroplating, Nickel plating, Sandblasting, Color painting Dacromet coating, Powder coating, customer requirement |

| Performance | Long lifespan, High precision, High wear resistance, High strength,Low noise, Smooth and steady, Fatigue strength |

| Model | Type A , Type B , ANSI, DIN , JIS Standard, Non-standard (single duplex and triple) 25A, 35A, 40A, 50A, 60A, 80A, 100A, 120A, 140A, 160A, 25B, 35B, 40B, 41B,50B, 60B, 80B, 100B, 120B, 140B, 160B, 180B, 200B, 240B |

| Packaging | Products carefully packaged,Inner plastic bag and outer carton box or customer requirement,after long distance transport or long time store, open the package, brand new, no damage no rust. |

Welcome your enquiry

When you work with Daxin Metal, you’ll have access to a professional team with years of experience fabricating Carburizing Of Sprockets.

For a timely quote, please complete and submit the following information. We are ready to address your questions and special requests to support you on your engineering challenge.

Our team will immediately reply your project inquiries to your email

Packing & Delivery

1. Testing 2. Assembling 3. Packing

4. Sealing 5. Loading 6. Shipping

|

PACKING

|

Inner Packing: Carton, Standard export packing or According to customer’s requirement Outer packing: wooden cases or According to customer’s requirement

|

||

|

SAMPLE TIME

|

6–15 days

|

||

|

PRODUCTION TIME

|

15–45 days or According to customer’s requirement

|

||

|

DELIVERY CLAUSE

|

FOB Tianjin, CFR, CIF, Express delivery

|

||

|

PAYMENT CURRENCY

|

USD

|

||

|

PAYMENT METHODS

|

T/T, L/C, MoneyGram, Other payment terms we can negotiate |

||

Questions and Answers:

Q: Can I get a sample?

A: Yes, we’re able to supply stock samples without charge but we need you provide your account of express.

Q: How many days can I get the product if I place an order?

A: For stock order, you’ll received them in 3-5 days by express and 15-25 days by sea shipment.

Q: What is the terms of payment?

A: For the convenience of business, we normally accept T/T,Western Union,Paypal for the instant payment.

Q: How much money of the advance payment should I pay for the order?

A: For small order that less than $5000, you need pay 100% for the order value; For those amount over $5000,we will ask you pay 30% of the total amount as the advance payment.

Q: Do you have any aftersales service?

A: Yes we have a perfect after market service for all the customer. If you get any problem, we will reply you at the first time and supply the best solutions to solve the problem.

Q: Is there any discount or promotion for customers?

A: Yes, we will have a good discount for our stable customer. In addtion, we will send special and beautiful gifts at the christmas or new year to all customer.

Welcome your enquiry

When you work with Daxin Metal, you’ll have access to a professional team with years of experience fabricating sprockets and gears.

For a timely quote, please complete and submit the following information. We are ready to address your questions and special requests to support you on your engineering challenge.

Our team will immediately reply your project inquiries to your email